MISSION STATEMENT

Satis Coating aims to supply quality chrome plating plastic components to automotive industry.

We provide Tier 1 to Tier 3 automotive company suppliers in Europe with our extensive experience on molding parts for chrome plating and plastic electroplating. Our engineers work in partnership with our customer developers to optimize part design performance and manufacturing efficiencies.

Satis Coating offers a variety of finishes from bright chrome to black including an extensive panel of Satin chrome approved by the major constructors. We plate ABS and PC/ABS substrates, in 1 and 2K configurations. Our dedicated R&D pilot plant facility is continually innovating new chrome finishes and product enhancements.

We aim to supply Quality Products, on Time Deliveries on a on-going Continuous Business improvements frame.

SOME OF OUR KEY DATES...

2004 – Opening of a brand new Chrome Plating plant for plastic bonding (ABS), prepared for automotive parts production.

2014 – Acquisition of a Pilot Plant for Plastic Chrome Plating from AIDIMME (Metal-Processing Technology Institute, Valencia), and JV for testing Innovative projects such as chrome plating on Polyamides, retro-lightened 2K parts and CrVI free processes.

Dec. 2014 – In order to improve the management and enhance the quality of the process up to Automotive industry standards, founder’s Family sell the majority to highly experienced shareholders.

Jan. 2015 – The newly branded company SATIS-MIRA S.L., starts with a deep reorganization at all levels.

Mar. 2016 – The remaining shares held by founder’s family are acquired by new Management. SATIS-MIRA S.L. changes its name into SATIS COATING S.L.U.

CAPABILITIES

Lines dimensions:

Production line en Castalla (Alicante –Spain): 1500 x 1500 mm.

Pilot plant in Parterna (Valencia-Spain): 600 x 600 mm.

Finishing:

Bright Chrome

Satin Chrome.

Black Chrome.

Colored Chrome with different finishing.

Micropores for exterior parts.

Base parts raw materials for 1L and 2K parts:

ABS.

2K PC. / ABS.

ABS / PC.

WHAT OUR COMPANY IS CAPABLE OF...

[rev_slider capability]

QUALITY POLICY

“Quality is meeting customer expectations, means supply the product according to the defined requirements and expected term.”

This requires the commitment of each and every one of us to develop our work as we defined in our Quality System:

Involving us all in compliance with the procedures and instructions defined in our Quality System in order to meet the objectives of the company.

Establishing and following processes aimed at customer satisfaction.

Following a philosophy of continuous improvement by encouraging our project teams preventing problemMonitoring our level of quality and setting annual objectives known throughout the organization.

Training the staff adequately.

Equipping the organization with the necessary resources to achieve customer satisfaction.

Satis Coating integrates continuous improvement as a philosophy of work through which we can become a better company for our employees, shareholders and customers.

WHAT WE MEAN BY QUALITY MANAGEMENT...

ISO certified UNE-EN-ISO 9001:2008:

On-site control process with full equipped laboratory.

Complete finished parts testing at AIMME.

Know how transfer from suppliers (ENTHONE, COVENTYA, ATOTECH…).

ISO/TS-16949 (2018) on going process for appliance in 2019.

[rev_slider quality]

R&D

Our latest developments are the evidence that our company permanently focuses on R&D:

Pilot Plant for Plastic Chrome Plating from AIDIMME (Metal-Processing Technology Institute, Valencia), and JV for testing Innovative projects such as chrome plating on Polyamides, retro-lightened 2K parts and CrVI free processes.

New processes environmental friendly.

New finishes corrosion resistant and new colors.

R&D BY SATIS COATING...

[rev_slider rd]

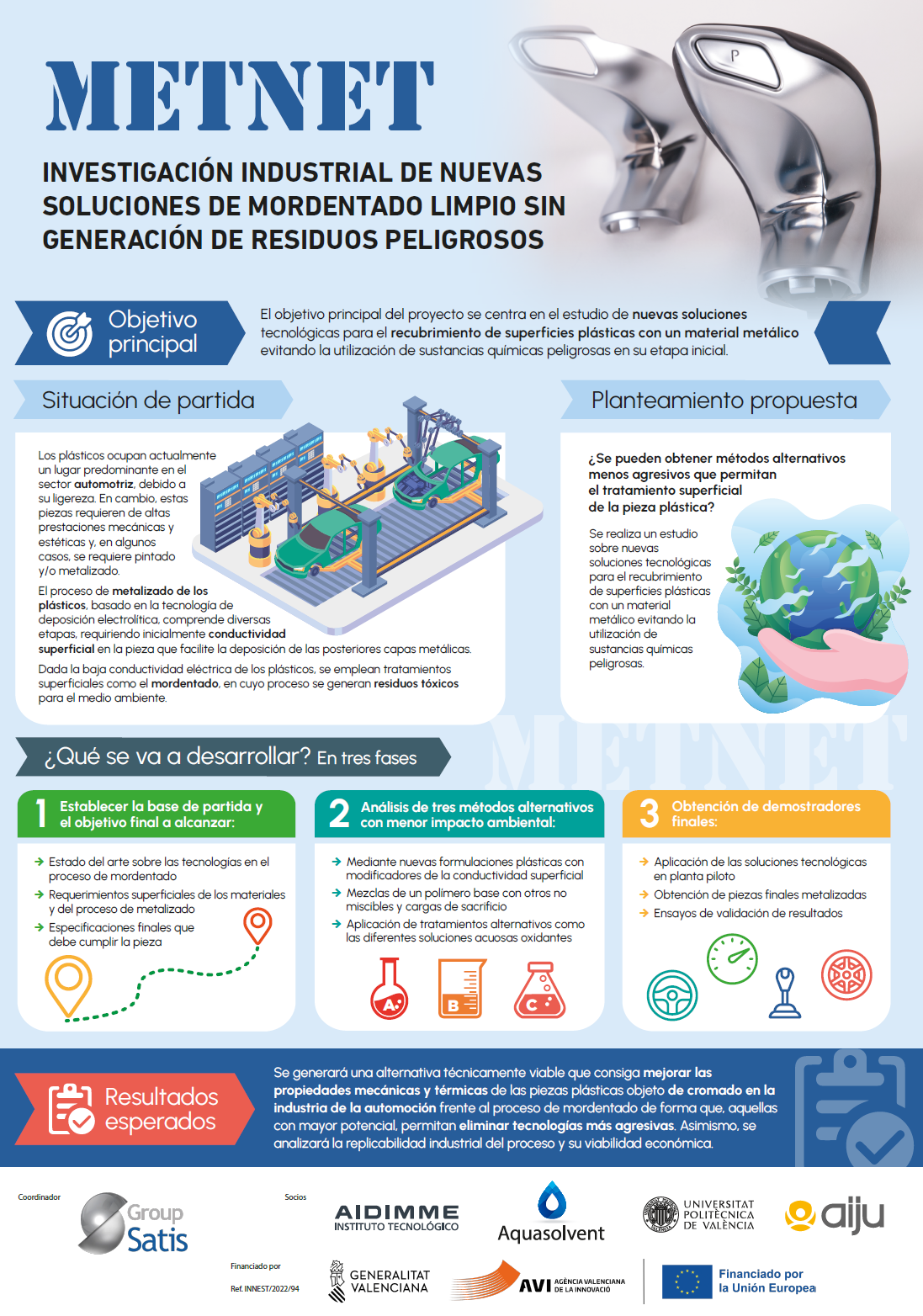

The METNET project seeks to develop new technological solutions for the coating of plastic surfaces with metallic material, without generating hazardous waste. Its objective is to improve the metallization process in the automotive industry through less aggressive and more sustainable methods. The project will be developed in three phases: analysis of current technologies, research into alternative methods with less environmental impact, and validation of these solutions in a pilot plant. It is expected to obtain a viable alternative that improves the properties of metallized plastic parts, contributing to a greener and more efficient industry.

ACTUAL PROJECTS

VW 3Q7 Satin Chrome Interior – Polo 2014 + Polo 2017 + Polo Cross 2017

FORD Satin Chrome Interior part for Titanium platform – Focus

PSA Satin Chrome buttons – Citröen DS5 + Citröen C4 Cactus

OPEL Bright Chrome Interior part – Adam + Corsa

RENAULT Real Satin Chrome Interior part for SWB platform + 2K parking button – Espace

RENAULT Real Satin Chrome Interior part 2K lasered plating technology – Clio

RENAULT Real Satin Chrome Interior part for HFE Kadjar platform + Door Panel ring – Kadjar

SEAT Bright Chrome Interior part – Ibiza 2017

PSA + OPEL Satin Chrome – C3 Picasso + Meriva 2017

SUZUKI Bright Chrome Interior – Grand Vitara

SOME OF THE PARTS ON WHICH WE DEDICATE OUR EXPERTISE TO...

[rev_slider productos]

CONTACT

SATIS COATING S.L.U.

Pol. Ind. II – Calle Bañeres, 6

Apartado de Correos 124

03420 Castalla (Alicante) – Spain

Phone: (+34) 96 556 14 81

A USEFUL MAP TO COME TO VISIT US...